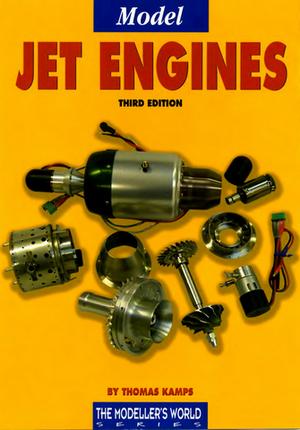

Реактивные двигатели

The radial compressor is much simpler in construc-

tion and therefore much more suitable for model

engines. The air flows into the wheel in the axial direc-

tion and is then flung outward by centrifugal force. On it

own this device is known as a centrifugal compressor.

Once again a single stage consists of a rotor and a stator,

although the pressure increase per stage is much higher

than with an axial compressor stage. As a result gas tur-

bines with radial compressors can often manage with

only one stage.

Additional advantages of the radial compressor are its

robu t nature and ib inherent reliability. The disadvan-

tage is the large frontal area of the machine. Gas turbines

with a radial compressor are therefore always somewhat

builT

The second contmuous flow machine in the gas tur-

bine b the actual turbine. This can be visualised as a com-

pressor "in reverse". The turbine converts pressure

energy into the shaft power which is required to drive

the compressor. Since the hot gases contain much more

energy than the compressor absorbs, the system is self-

sustaining. If the final temperature after the combustion

chamber - what is known as the combustion gas temper-

ature - is high enough, additional power can be extracted

from it.

Like the compressor, the turbine itself may consist of

one or more stages. When the air reaches the turbine

stage it first flows through the stator which converts part

of the pressure energy into kinetic energy. As the gases

pass through the fixed

stator they are accelerat-

ed in the direction of

rotation of the rotor.

@ 2005 Traplet Publications Ltd

Год 2005

Язык Английский

Скачать Реактивные двигатели zip 6Mb

Пропеллеры деревянные

Пропеллеры деревянные Аккумуляторы Li-Po

Аккумуляторы Li-Po